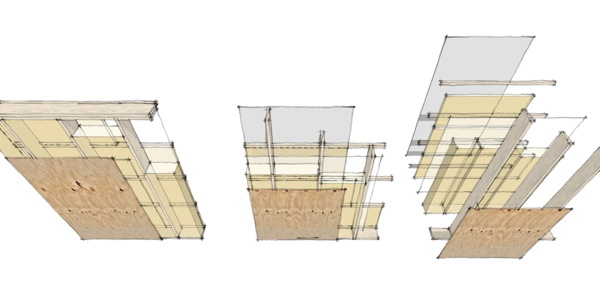

We've been kicking this idea around for about a year, ever since we created our 0970 Lagom House for a design contest. Inspired by our study of Swedish construction we wanted to create a high performance wall for the US market that lent itself to panel fabrication, and was accessible to any builder using the skills and experience they already have.

Why not use new materials and techniques? How can you make a New Wall that everybody is going to know how to build? We want to create a wall that can be widely adopted, something that any builder can start building tomorrow without any new training, without finding any new suppliers, with out changing the way they run their business. If we want the greatest number of builders to build more efficient houses we need a wall they understand immediately, we need a wall that they can purchase materials for from their existing suppliers, use their existing sub-contractors, and a wall that is familiar enough for them to reliably price and schedule. New materials and new techniques throw off all of this and become barriers to adoption. We don't want barriers. We want everybody to start building more efficient houses. Continue reading for a detailed explanation of this simple but robust wall.

We proposed an initial version of this wall when we designed the Lagom House, but now we believe we've made significant improvements. Gone is the exterior foam insulation layer. Foam insulation is expensive, and it is difficult to place on the exterior without creating an unwanted vapor barrier. Instead we rely on lessons from the Swedish wall to replace the thermal break that foam offers.

First we are starting this with a wall design for northern climates. Designs for southern climates are different, particularly in the vapor profile. So keep in mind this design is for a heating centric climate. We are planning this wall for 2x6 or 2x8 versions. The 2x8 versions offer a greater insulation level for those that desire it. Starting from the interior here are the layers of the wall system.

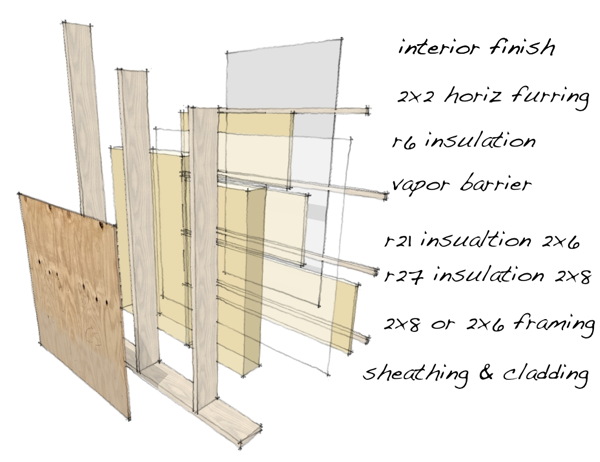

• Interior finish is assumed to be gypsum wall panels, the commodity wall finish in the USA.

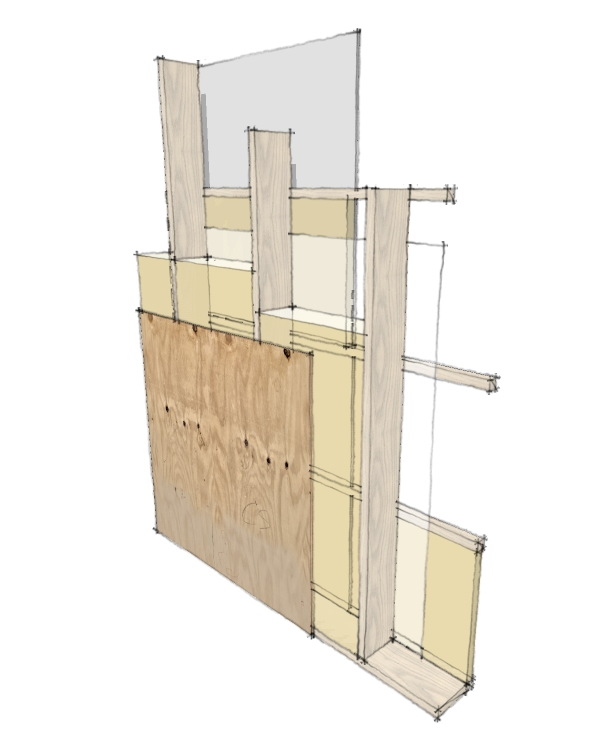

• Next we have an electrical and plumbing furring space. This space is created with 2x2 furring members, and is insulated with fiber glass batts, 1.5" thick for an insulation value of R6-6.5 depending on the product chosen. This insulation is typically more rigid than batts and is sold as a fiberglass "board". This actually facilitates cutting openings for electrical boxes and other penetrations. The horizontal furring allows the insulation layer to break the thermal transfer of the main stud wall in the same way exterior foam insulation does, but it does so with out creating a problematic exterior vapor barrier, without expensive foam insulation, and with the added benefit of a dedicated wiring chase space that allows us to build a tighter primary wall. Thank you Sweden.

• Next is a continuous vapor barrier - a plastic sheet that runs continuously from top plate to floor plate. Because all of our wiring is in the furring space there is no reason to penetrate this vapor barrier allowing for a very air tight wall to be created.

• Next is our insulated stud space based on 2x8 or 2x6 studs, 24"oc will suffice for these strong studs. Un-faced batt insulation can be used since we have an independent vapor barrier layer. And since there is no wiring or other obstacles in the wall the batts can be installed neatly, and completely filling the voids. Batts have a bad reputation for sloppy insulation. One thing the Swedish walls show us is that its not the batts, but the obstacles that are the problem. These walls can be as tightly filled as any highly insulated wall without the wires and piping to struggle against. Now what insulation to use? The major insulation manufacturers in the US offer two densities. Always choose the higher density with the higher R value. For a 2x6 wall that will be R21 batts. For the 2x8 wall we have quandary - US manufacturers do not make batts for 2x8 walls. 2x6 walls, yes. 2x10 ceilings and floors, yes. 2x8s you are out of luck. Until they begin we have two options. We can use 8" R30 batts, and compress them 1" into the 7.25" space of a 2x8. This will diminish their R value somewhat - don't count on more than R28. Or you can do two layers: a 1.5" R6 + a 5.5" R21 for a total of R27. In the meantime, Owens Corning and Certainteed - WAKE UP! We need wall batts for 2x8 walls.

• Last but not least is our sheathing and exterior wall system. This remains open ended. Commodity builders are going to want to use their composite Zip sheathing and cheap vinyl siding. Green builders will use a sophisticated rain screen cladding system. And everything in between. All will work here.

Once accounting for total wall R values that take in studs and solid framed portions of the wall you can probably expect the 2x6 wall to come in R23-24, and the 2x8 wall R30-31. This is clearly enough to contribute to a Passive House, but even if you are not looking to build a certified house you have an easy to build high performance wall using commodity construction products. If we can get builders making houses with walls like these then soon we can forget about certifying standards and just build every house to a high level of performance. We can do this now. Its time to demand it.

Tidak ada komentar:

Posting Komentar