One issue we have not examined as we looked at the fabrication of houses in the factory is the foundation work that goes on in advance of the arrival of the house. The Swedes are using some innovative products for foundations as well, products that make there status quo houses much more energy efficient than ours here in the States.

New houses in Sweden are primarily built on slabs, partly because its expedient, but also because its naturally the best way to have in floor radiant heating. In a cold climate this is the only way to use a slab otherwise your slab will feel cold and uncomfortable. But a slab in a cold climate must be insulated from the elements or it will throw heat out its edges. There are typically two strategies to isolate your slab from the cold.

The first strategy is to make an insulation break between the slab and the foundation wall. This is typically done with a narrow insulation layer. In order to place this between the slab and wall the two structures have to be built in separate operations. First the wall, insulation break, and then the slab is poured inside the walls. Two steps.

The second strategy is to insulate the outside edge of the slab. This allows you to pour the slab and foundation wall in a single step, but you have to return and install insulation around the perimeter. Thats not the end of it though. This insulation is of course very vulnerable to damage. Its a soft material and it is right at grade, so it must be protected by something tough, usually the best choice is a cement board product. The insulation and protection board creates at best a second step.

Ok, what are the Swedes doing. First of all they are not building deep foundations. All buildings in cold climates should be founded on soils below the frost line. How do the Swedes avoid this then. I''ve not seen photos of their entire site prep sequence but they appear to be setting slabs on stone beds which may reach below frost, and prevent soil expansion if frozen. Furthermore they are building on slabs insulated at the perimeter which allows the radiant slab heating system to warm the earth below the center of the slab which prevents soils below the foundation from freezing and heaving. So suddenly they have eliminated the foundation wall and only need to build the slab on grade. A great savings in time, effort, and expense. Ok, but they still end up with the slab insulation issues described above. No. They use a foam formwork that forms the perimeter of the slab, and insulates it at the same time. And this foam formwork is coated with a tough cement finish coating that protects the foam and prevents it from being damaged. Even more important, its one step.

Laying out the slab - corner pieces are place first.

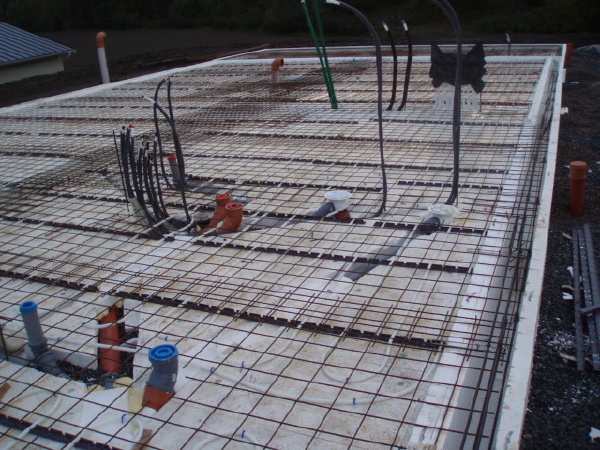

Ready for the pour, edge forms, wire mesh, plumbing, and heating loops all in place.

The slab poured. Once cured its ready to receive the prefab house.

Here is an example of a Swedish manufacturer of these foam forms:

Previously:

Letters from Sweden - deliver and set

Letters from Sweden - plumbing the prefab

Letters from Sweden - wiring zen

Letters from Sweden - a windows tale

Letters from Sweden - panel building in Sweden vs the USA

Letters from Sweden - Europe is different, Sweden is not, sort of..

Letters from Sweden - land of modern, land of prefab

Letters from Sweden - conversations with an expatriate builder

Technorati Tags: modern design, modern house, prefab house

Tidak ada komentar:

Posting Komentar