So called Advanced Framing has been promoted as a technique to improve efficiency and energy performance for house walls. But it also seems to have been designed to ensure that nobody adopts it.

First we should cover the basics - what is Advanced Framing? It is a "system" or practice of house framing that endeavors to reduce the amount of wood going into the wall, and as a result reduce thermal bridging and increase energy efficiency. It is also interchangeably referred to as Optimum Value Engineering or OVE which perhaps speaks more to the process that came up with this. Value Engineering has come to be a euphemism for cutting costs. In this case, cutting out everything but what is essential to frame a house.

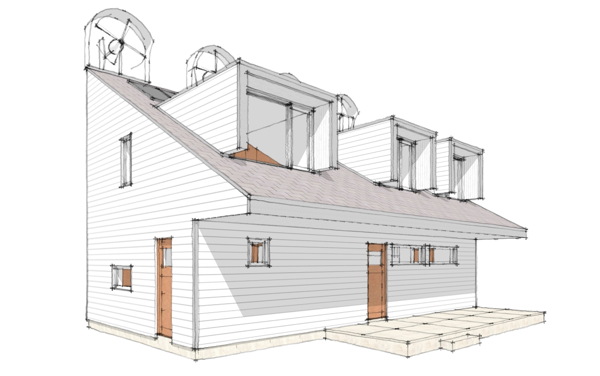

Before we look at exactly how Advanced Framing accomplishes these goals let me just air my gripe. The details of the AF framing techniques are smart, efficient, and dare I say common sense. Yet taken as a whole "system" it is overly rigid, inflexible, and lacks resiliency. To follow a strict application building elements must fall on the proposed modular grid. This limits possibilities, and dooms existing house plans to significant redesign. Its lack of resiliency means its advantages can be quickly overcome by deviation from its strict use. And while it can save up to 20% in material, it really does not go far enough to create a high performance wall system. I feel this combination is a barrier to adoption that will prevent it from becoming the de-facto method for framing houses in the US. Yet many of the individual details are easy to implement, and many builders have already taken this hybrid approach. With the help of this diagram lets look at some of the key aspects of AF, the ones that are easiest to adopt.

Framing spaced at 24" on center. This is a common sense approach. As we put more insulation in our walls we move to larger studs. 2x6's are common, and I'm advocating for a move to 2x8s. These larger studs are strong enough to be spaced at 24"oc, rather than the 16"oc common with 2x4 walls. This wider spacing reduces the amount of wood in the wall, and increases the amount of insulation. Roof framing is easy to space at 24", and engineered lumber floor joists can span further than solid wood at 24" spacing. So yes, we can do this, easily, and it makes sense.

Lets look at the window and door openings. You will note in this diagram that there is a single stud at the side of the window opening. The window header, and the window sill frame are supported with metal clips mounting them to the single adjacent stud. In conventional framing there would be three studs here. A king stud that ran from sill to top plates. A jack stud which ran up to the underside of the header and supported it, and a similar stud for the sill called a cripple. By the time we reached the sill plate the jamb is three studs wide. A common hybrid is to simply remove the cripple studs and move to two studs, and for larger window openings with a bigger header this makes sense. This is easy to do no matter how the whole house is framed.

Insulated headers are another great practice here. Especially as we move on to 2x6 and even deeper 2x8 walls, we can now provide an insulation layer between the interior and exterior header members. This prevents the wall above the window and door openings from becoming a thermal bridge. There are even some products available that pre-assemble the header members with an insulation core.

Two stud corners are another easy to adopt practice. The AF wall has two studs at each corner, one oriented towards each wall panel that meets at the corner. Traditional framing would have a third stud which served to support the interior wall board at the corner. In the AF wall that is replaced by a metal clip, or a 1x nailer. This practice keeps the corner from bulking up with solid wood, and allows insulation to extend into the corner framing. Again, easy to do.

All that sounds good, so where is the problem? The problem is with the next element that AF seek to reduce. Instead of being easy to implement, it is difficult to implement, and instead of being a tidy self contained solution it is a solution that imposes on the rest of the entire house framing to pull it off successfully. I am talking of course about the "Single top plate". Perhaps the shortest note in that diagram causes the biggest trouble. Lets look at this.

The idea is simple. Walls are traditionally built with two top plates. That means in a 2x6 wall the studs are topped off by two 2x6s horizontal capping the studs and creating a bearing surface for floor framing and roof framing. Two studs are used because that gives the top plate enough strength to support a floor joist or roof rafter that does not fall directly above the stud below. But of course two top plates makes for a lot of solid wood through the wall - a thermal bridge. AF aspires to reduce that to a single top plate, cutting the size of the thermal bridge in half. But at what cost? In order to eliminate one of the two top plates we now have to ensure that the floor joists fall directly above the stud. In a two story house we also have to ensure that the studs of the wall above also align, as well as the roof rafters. Suddenly everything has to line up.

In concert with this AF proposes we eliminate the rim joist which is a solid piece of wood equal in depth to the floor joists that runs the perimeter of the wall. This rim joist aids in transferring mis-aligned loads from one floor to another. So studs in the second story wall need not align with the studs below. Without a rim joist, again, the studs above must align directly.

So how does this play out? Well its suddenly a great benefit to make all window and door openings fit within the spacing of the studs. Imagine if you have a window on the second floor that does not fall on the grid. This means a jamb stud will not be aligned to the studs below and some special care must be taken to support the load from its header. Another concern is engineered wood I beam joists. Without a rim joist hey are not strong enough to transfer the vertical loads by themselves and would require stiffeners. So either we return to using solid wood joists and the shorter spans they require, or we spend the labor to reinforce the ends of every joist. Lots of labor is rarely a good trade for a little material. We can add more studs to resolve these issues, but suddenly our 20% gain in material is dissolving.

What we are left with is an extremely rigid system for laying out a house on a grid. And all the flexibility we've given up is solely for the sake of losing one of the top plate members of the wall. This is simply not a well reasoned trade-off. In the end, its a deal killer. Designers find it frustrating and limiting. Builders are forced to completely redesign their stock of house designs. And in the end the return on performance is not that great. The wall studs still have no thermal break, and the performance is only slightly better than a conventionally framed wall.

Lets stop pretending that this is a "system". What we have here is a handful of helpful framing strategies, and one nearly preposterous idea about how to frame a house that nets a very small improvement in thermal bridging. Its time to stop patting ourselves on the back pretending we've really accomplished something with a claim of using "Advanced Framing" techniques. Some might call it "greenwashing", I just think its kidding ourselves. We need to do much more than this to build a high performance wall. We have better options.